Satellite propellant tank solution highlights Spincraft capabilities in European Space

The European space sector is experiencing a period of tremendous investment, growth and innovation. Spincraft UK, a Standex Engineering Technologies Group (ETG) company, has emerged as a valued supply chain partner to spacecraft manufacturers and Tier 1s in Europe. We have the advanced metal forming capabilities, processes, experience and certifications to deliver reliable, cost-effective solutions.

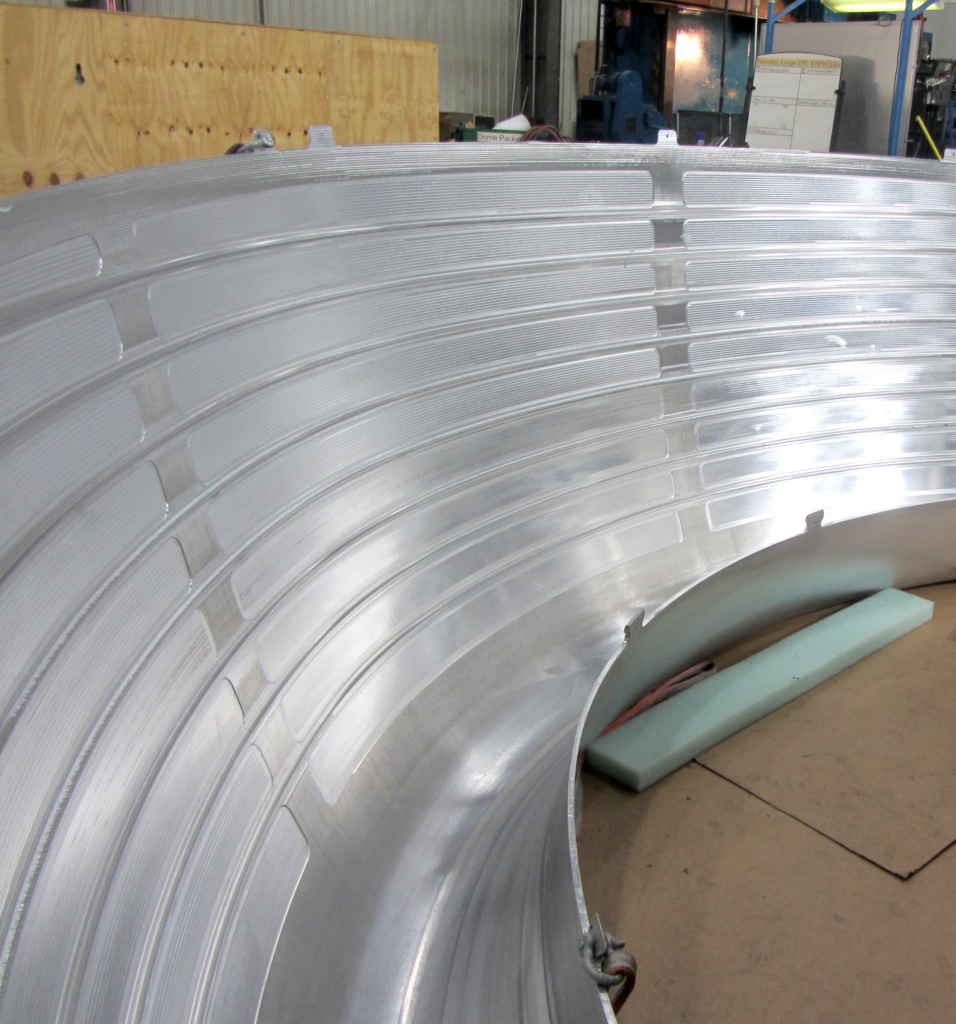

Core in-house capabilities at Spincraft UK include Spinning, Shear forming, Press forming, Machining and Fabrication. We also possess a robust supply chain with Heat Treat and other specialty services.

Prototype Tank Design

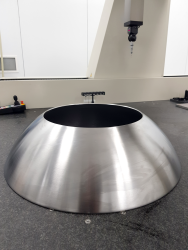

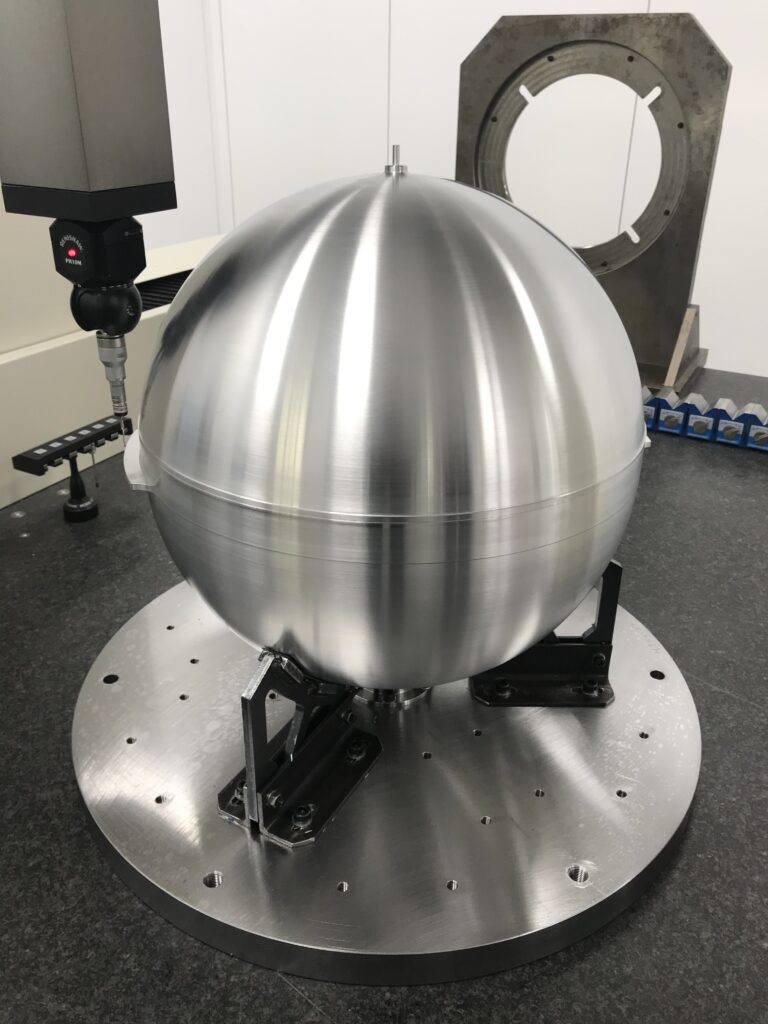

Recently we had the opportunity to assist a significant European satellite OEM on a project to manufacture the prototype propellant tank for their next-generation spacecraft. With the landscape of satellite tanks shifting to demisable aluminum structures that disintegrate upon re-entry into the atmosphere, our partner sought potential alternatives to their existing supply chain. Although this customer had a strong background in tank design, Spincraft was able to secure the work due to our industry and material experience, prototyping collaboration and convenient UK location. This project demonstrated Spincraft’s leading capabilities to this customer. It also served as a great learning experience for our team due to the challenging problem-solving required.

Keeping within cost constraints was critical for the customer. Knowing budget overruns were unacceptable, our team identified and executed part design modifications taking cost out while still producing a conforming unit. Customer collaboration and intimacy like this set the Spincraft team apart.

Putting our Global Expertise to Work

Though this was not a large tank, roughly only 1.5ft (0.5m) in diameter, aluminum construction was not typical as the UK site usually handled domes of more exotic materials including titanium and nickel-based superalloys. To execute the project most efficiently we leveraged our European dome pedigree with engineering expertise across ETG. Cross-site pollination devised the best method of manufacturing and custom tooling design to deliver required tolerances within cost parameters.

Spincraft first tapped its supply chain partners to obtain the desired pre-machined round preform. We then got to work performing the precision machining and generation of the prototype’s final parts. Visual storyboarding was a vital element in the machining sequence to the required contours. This visual aid offered a guide to outline the many steps needed to put together the completed fixture. Once both the upper and lower domes were machine-finished, Spincraft performed assembly fit-up checks to confirm that the weld interface region between the parts was suitable for downstream assembly in a cleanroom environment.

The Spincraft UK team faced a customer challenge with a non-typical material for the planned application, requiring absolute quality, cost control and precision. We used customer intimacy, cross-site collaboration and domestic production capabilities to successfully deliver this prototype to the customer within budget.

Connect with Us

The Spincraft team is a proven solutions provider in the European space market. Reach out to discuss how we can collaborate and support your metal forming needs.