ETG’s Expanding Knowledge Base

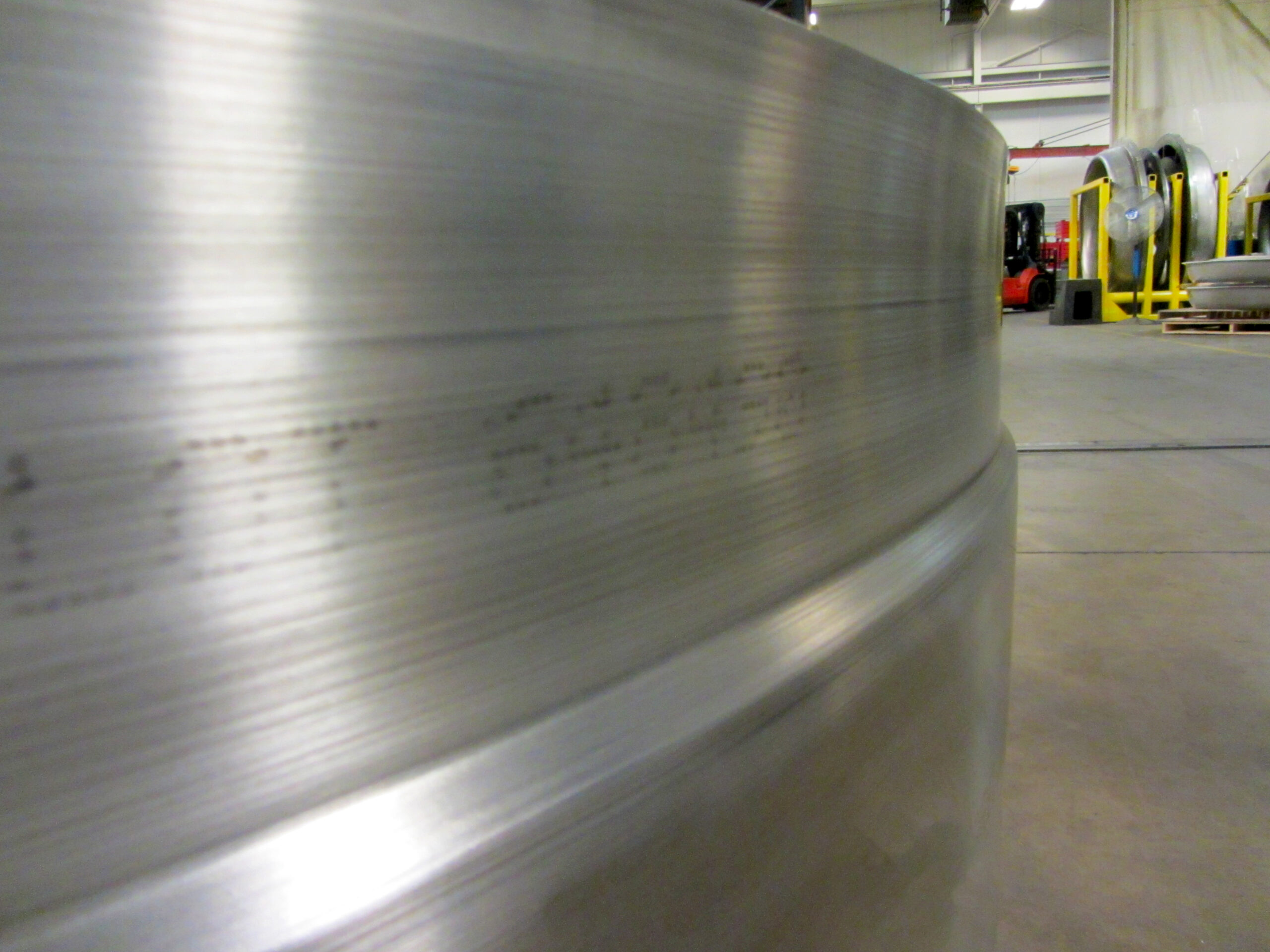

Standex ETG leverages deep expertise in expansion forming to deliver precision components with superior dimensional accuracy and repeatability to a wide range of aerospace and defense customers. Our Spincraft facilities in Massachusetts and Wisconsin house custom-designed, CNC-controlled expansion equipment engineered for both standard and highly specialized applications. We help our customers meet the most demanding specifications with confidence.