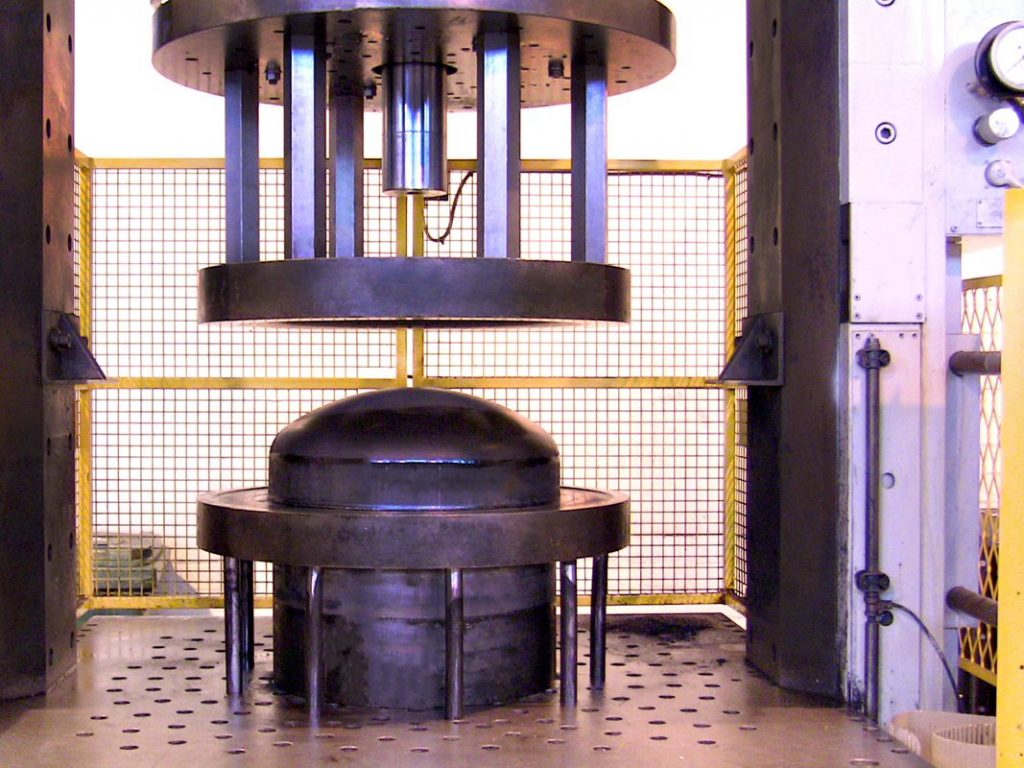

Press Forming

Professional Pressing

Our WI and UK sites offer press forming processes. These processes realize optimum product net or near-net shapes. Pressing enables transforming sheet metal into the desired shape while maintaining the strength and quality of the material. It allows for high repeatability and efficiency within the production process.

Versatility in our manufacturing processes and material capabilities allows our Advanced Engineering team to design and achieve optimum manufacturing solutions for our customers’ complex metal forming challenges.

We offer a Wide Range of Cold Forming Press Options:

- Forming pressures ranging from 150 ton up to 600-ton capability

- Platten sizes as large as 63” x 63” (1,600 mm x 1,600 mm) with a gap height of 63” (1600mm)

- Most presses have a third hydraulic cylinder to allow for reverse drawing and deep reduction on complex parts

Press Forming Material Capabilities

- Stainless Steel

- High Temp Nickel Alloys

- Titanium

- Aluminum