Advanced Metal Forming Solutions

About Spincraft | Standex ETG

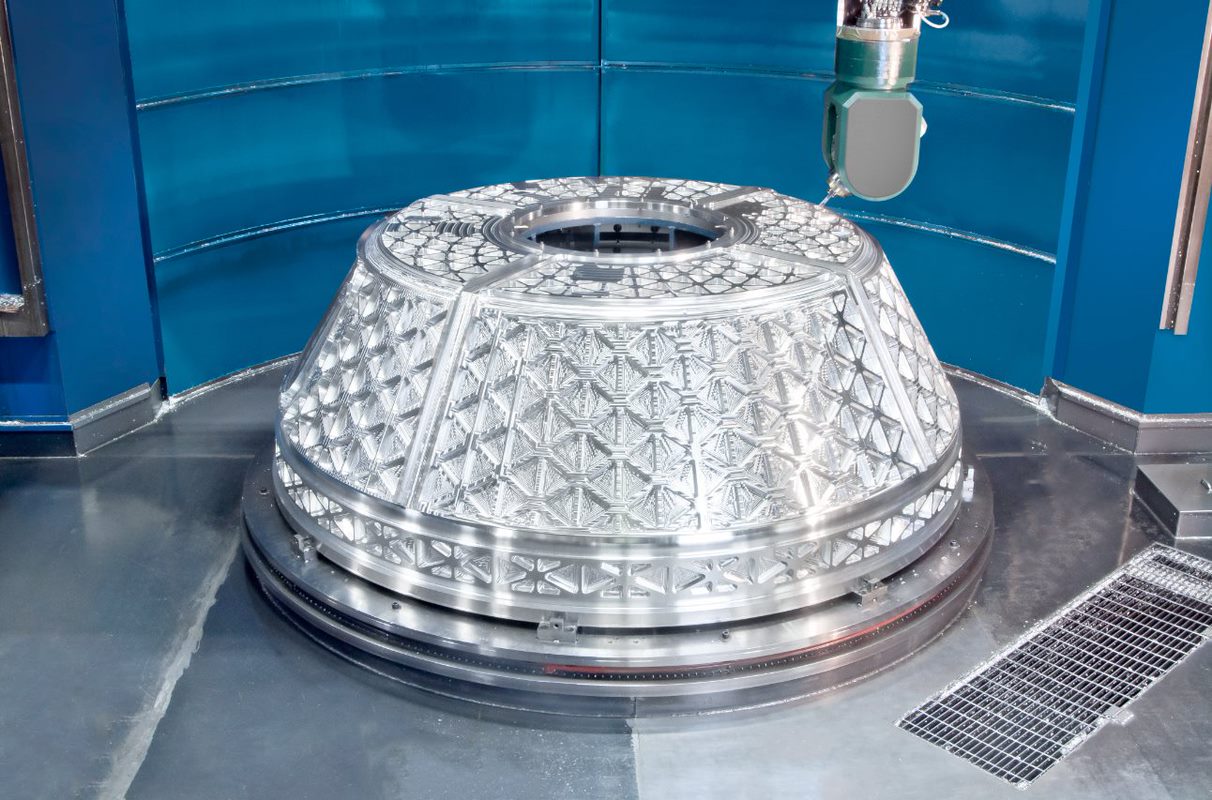

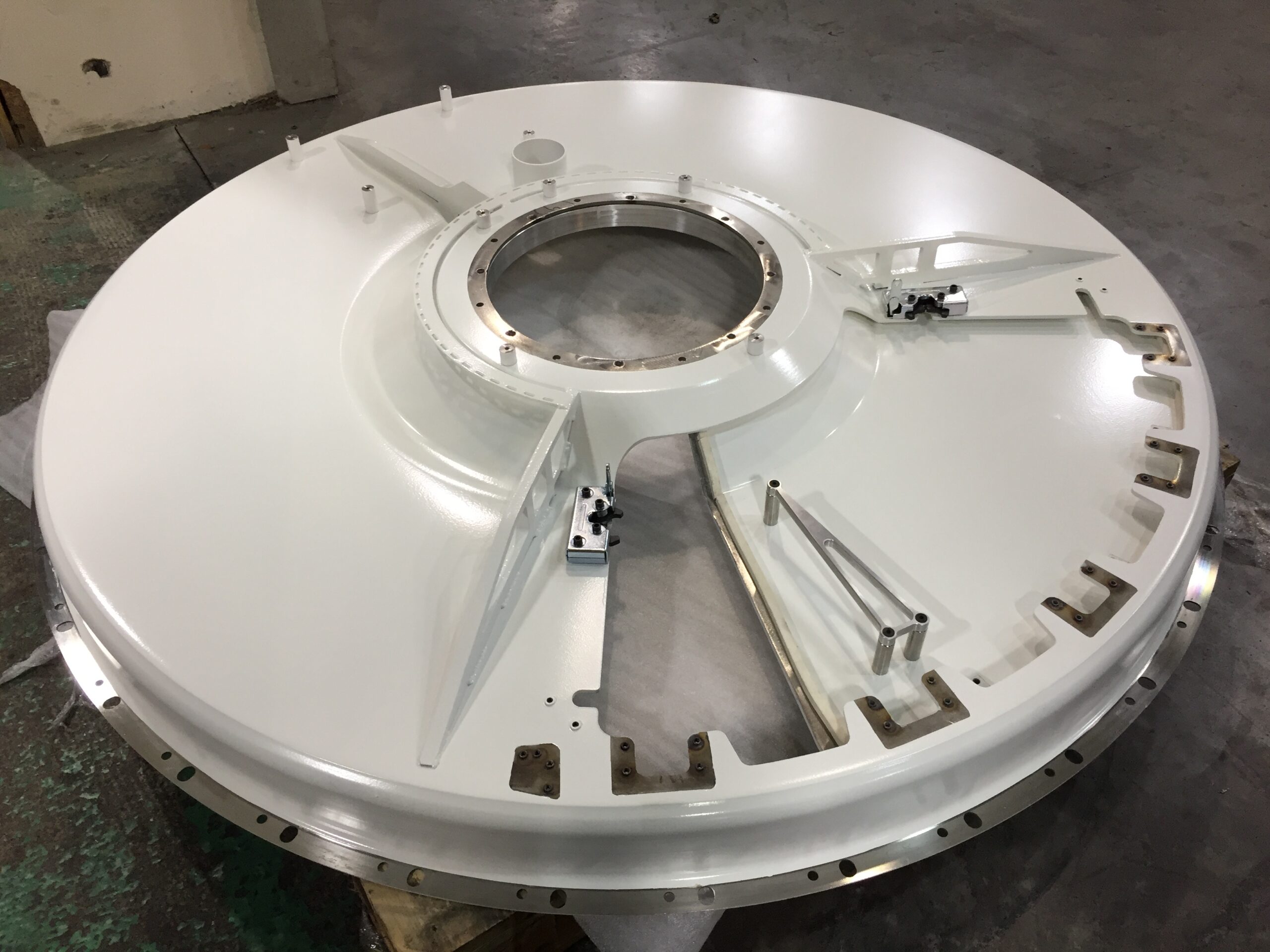

As a division of Standex International, the Standex Engineering Technologies Group (ETG) provides innovative advanced metal forming technologies. Through the Spincraft business, the ETG team applies these unique forming capabilities to design and manufacture cost-effective, single-source solutions for customers. Some of the diversified markets we support include aviation, space systems, defense, energy and medical systems.

Due to our state-of-the-art manufacturing facilities, we are able to offer in-house world-class forming capabilities out of our Boston, Milwaukee and Newcastle, UK sites. As a result of our streamlined operations, we possess more than a century of metal forming experience. This technology expertise spans across a wide range of specialty equipment.

It should be noted that the critical solutions we deliver through metal working encompass the following:

- Broadest selection of alloys

- Largest part dimensions

- Comprehensive thicknesses or thin walls

- The most complex shapes and contours

- Single-piece construction and/or complex fabrications

Use the links below to see the distinguished services and industry-specific solutions we specialize in. These examples provide a better understanding of the ways ETG can solve your greatest metal forming challenges within the following sectors

Aviation

Defense

Space Systems

Energy

Medical

Engineered Products

By establishing relationships and collaborating with customers, ETG is positioned to reduce costs and complexity. We can do this across an unmatched range of formed sizes, shapes and alloys. Through conventional and innovative methods, we are an essential contributor to our customers’ successes.

To demonstrate our services, check out what our customers have to say about us.

What Clients Are Saying

News & Events

Don’t miss a post! Aside from our social media channels, you can stay up to date on all the latest and greatest ETG news by checking out our News & Events section. Get a sneak peek by taking a look at what we’ve been up to lately with these recent posts.