Defense

Industry Expertise

The experience and capabilities developed by Standex ETG enable us to support the Defense industry with a wide variety of spun, formed and fabricated hardware components and assemblies. Our sites form today’s most advanced materials to the exacting needs of leading defense contractors and their suppliers. Similar to the Aerospace market, our defense customers demand the ability to achieve complex geometries and tight tolerances with exotic materials. All products are made with an absolute commitment to quality and in a cost-effective manner.

Leading Defense Solutions

ETG’s core competency of reducing material input weights, part complexities, assembly steps and overall production costs have created multiple market-leading solutions across the defense industry. Our solutions utilize core manufacturing processes including spin, shear and other forming and fabrication technologies in our portfolio. Our proven industry experience allows us to collaborate with customers to find performance enhancements and risk mitigations including part count reduction and the elimination of welds. ETG forming capabilities are augmented by vertical integration of heat treat, machining and testing that allow for simplified supply chains and turnkey offerings to the market.

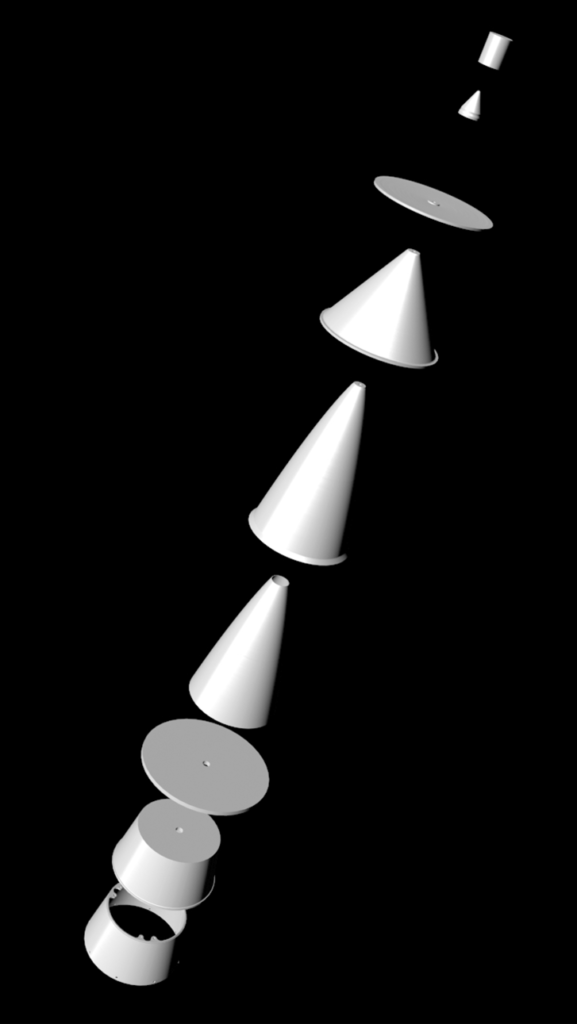

Missile

- Center Body

- Liners

- Nose Cones

- Shell Casings and Ancillary Components

- Warheads

Aviation

- Bulkheads

- Engine Hardware

- Exhaust Liners

- Inlet Lipskins

- Nacelle Components

- Particle Separators

Marine

Programs include products for applications both above and below the waterline; used for propulsion power generation or advanced weapons hardware. Equipment and processes can support key defense hardware requirements and precise tolerances.

- Propulsion Components

- Coupling Covers

- Fairwaters

- Mooring Bitts

- Rear Engine Shroud Covers

- Rope Guards

- Water Wash Rings

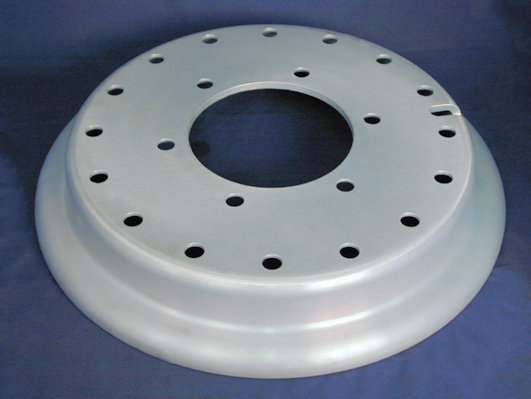

Vehicles

- Tank Wheels

- Track Inserts

Manufacturing Capabilities

- Spin Forming

- Shear Forming

- Expansion Forming

- Heat Treat

- Machining

- Fabrication & Assembly

- And Many More

Key Partnerships

We work with many of the world’s leading defense contractors and supporting Tier 1s.