Space Systems

Space Systems Industry Expertise

Over the last quarter-century, Spincraft has grown to become one of the most critical solutions suppliers to the space launch vehicle and space exploration markets. Our leading-edge forming processes and industry-best capabilities have made us a trusted partner in support of US national security efforts, ground-breaking NASA missions and next-generation launch vehicle development for leading public and private companies across the world. Spincraft now stands poised to facilitate and shape the next decade of space exploration and commercialization via our close collaborations with current and new partners.

Spincraft solutions have the ability to reduce part-count, eliminate welds and reduce weight; critical requirements within the Space Systems market.

Leading Solutions

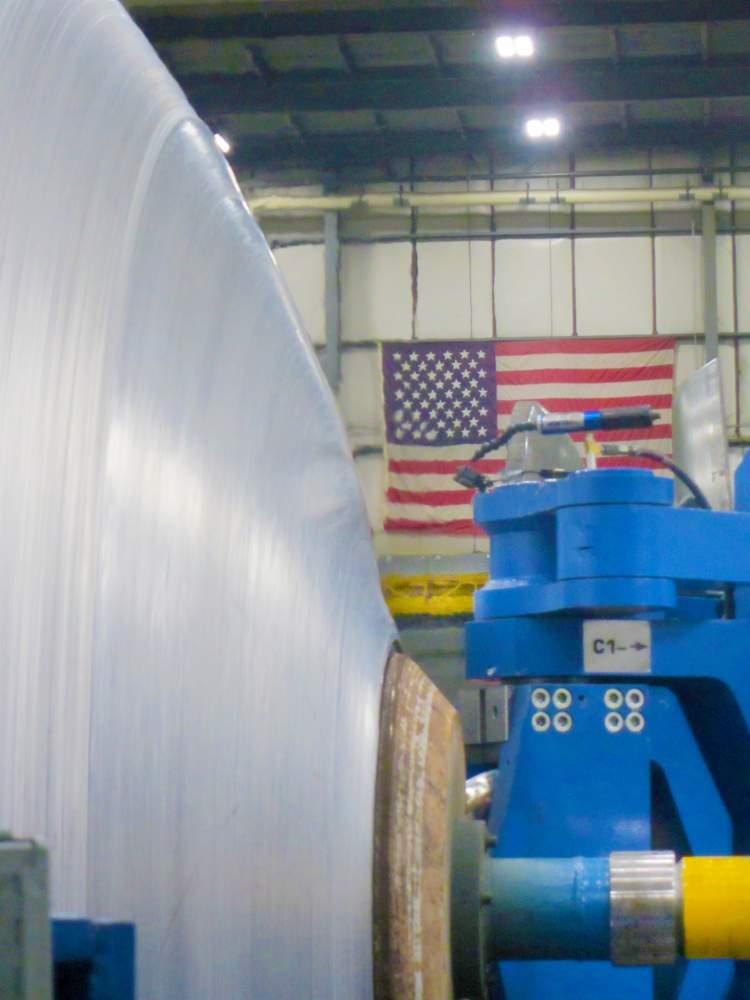

Spincraft has a long heritage of providing launch vehicle domes going back to the Titan program of the 1990s that gives us an unsurpassed understanding of large dimension forming for the Space industry. Combined with continued technology development and best-in-market equipment, our experience enables us to provide customers with turnkey large dimension single-piece domes and structure solutions. Spincraft’s pedigree provides our customers with additional benefits including reduced input weight and a more streamlined manufacturing process as well as reduced complexity and risk through the elimination of welds. As the go-to industry manufacturer, we can provide unsurpassed service and performance.

Launch-Vehicle Hardware

- Fuel Tank Domes to 17.7 feet (5.4m) diameter and beyond

- Bulkheads

Space Exploration Hardware

- Crew Vehicle Bulkheads and Structural Components

- Gateway, Habitat and Lander Infrastructure

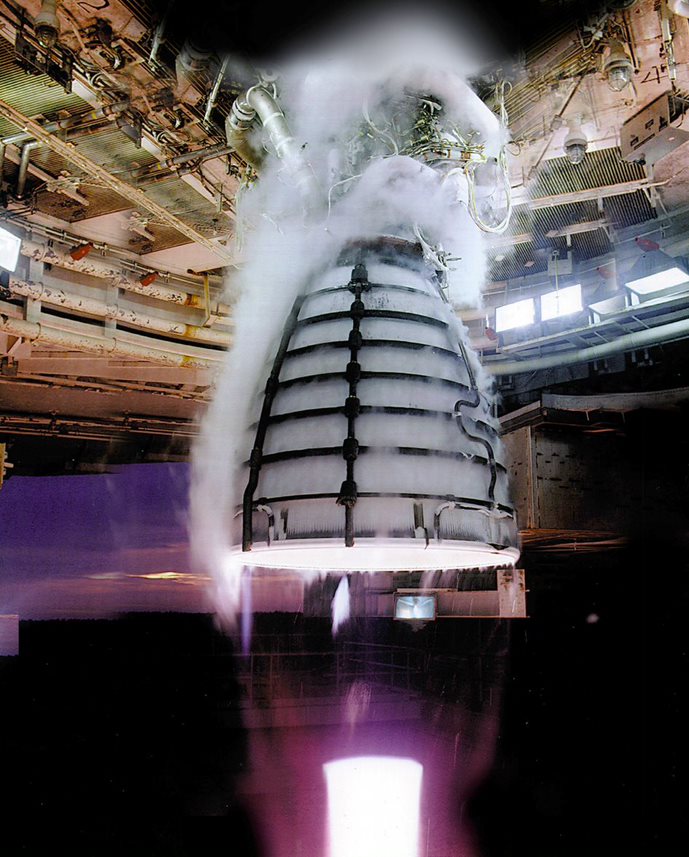

Engine Components

- Combustion Chamber Liners

- Engine Nozzles

- Integral Barrel Domes

- Thrust Cones

Tanks

- Cryogenic Tanks

- Internal Tank Separator Cones

- Pressurant Tanks

- Tank Components and Assemblies

- Tank Liners

Manufacturing Capabilities

Spincraft can provide spin forming and expanding capabilities as well as project management for domes and qualified tanks including chem processing.

We provide full-service heat treatment for aluminum, ferrous & non-ferrous alloys; our full-service machine shops offer 5-Axis CNC up to 230” (5,842 mm) diameter and 118” (2,997 mm) height. Our engineers are skilled in Program and Sub-Contract Management and support Developmental projects as well as long-running programs.

Engineers work with a variety of design software systems:

- Internal DPD (Digital Product Definition) Process manages customer model data.

- TransMagic software verifies that converted model data remains accurate to native CAD data.