Spincraft: Leading Space Supplier with Advanced Forming Capabilities

Space Launch Vehicle & Structures

The rapid commercialization of space and recommitment to exploration are fueling innovation across the space launch vehicle and structures sectors. New products and complex designs require clever manufacturing approaches to minimize input weight and provide the most cost-effective solutions. Spincraft’s capabilities and experience offer the perfect combination to support these industry demands and technical requirements.

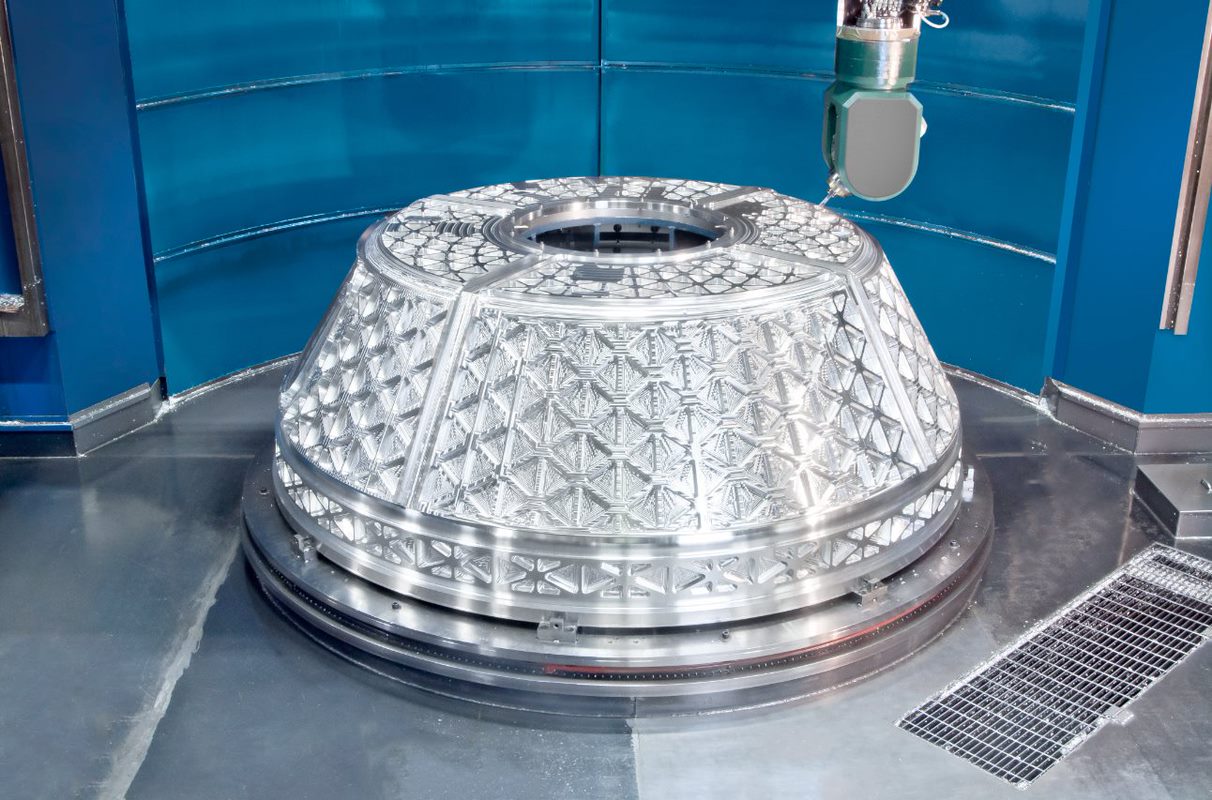

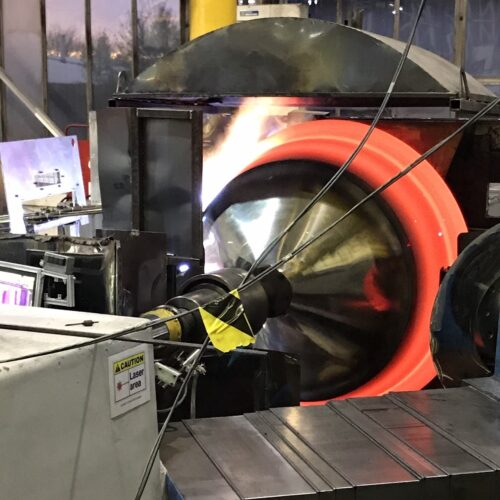

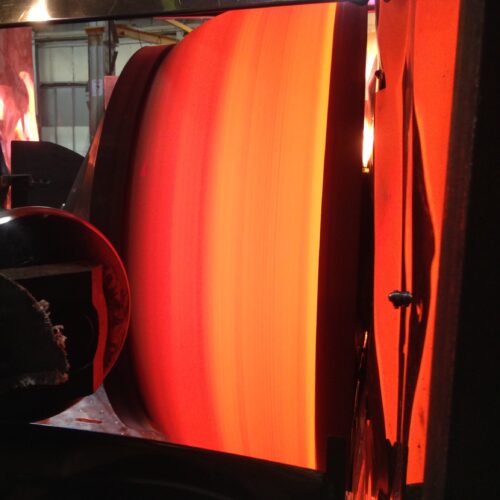

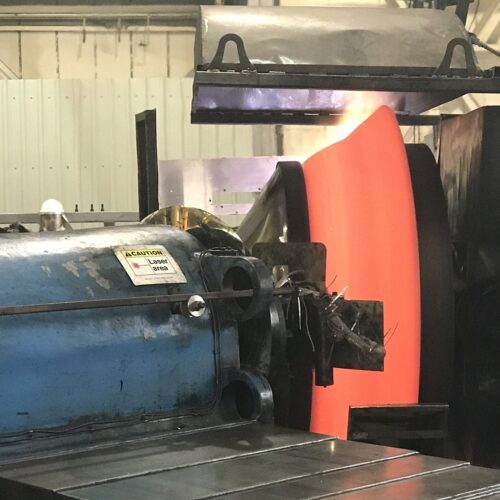

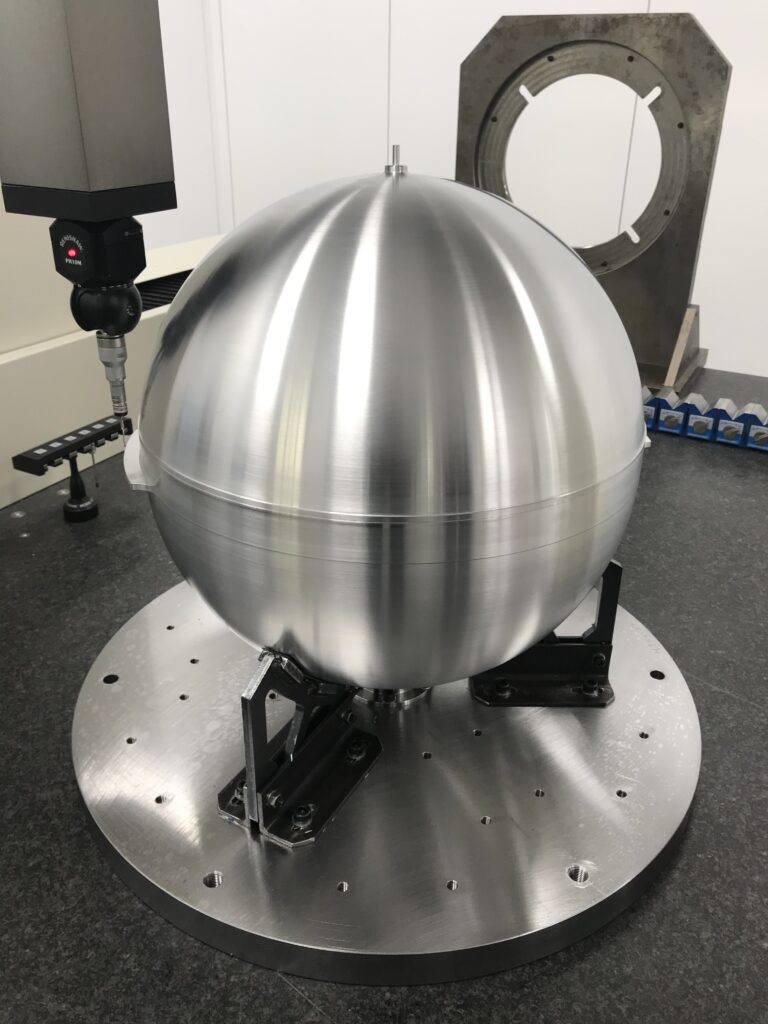

Our Spincraft facilities operate some of the world’s largest spin forming equipment. This allows us to provide complex geometries in thick-walled cross sections from all formable metallic alloys that are critical to meet aerospace requirements.

Various aerospace applications benefit from Spincraft’s unique forming capabilities. Spincraft has provided the industry with considerable variations and sizes of fan shrouds and tank sumps for over 26 years.

Spincraft’s distinctive abilities allow our customers to design parts with complex features that significantly optimize part mass and aid downstream manufacturing and assemblies. The curved geometry of these parts is readily formable in heavy thick-walled sections giving Spincraft a leading edge in meeting specialized customer demands for high precision and low-mass components. These are essential specifications necessary to deliver crew and cargo to orbit and beyond.

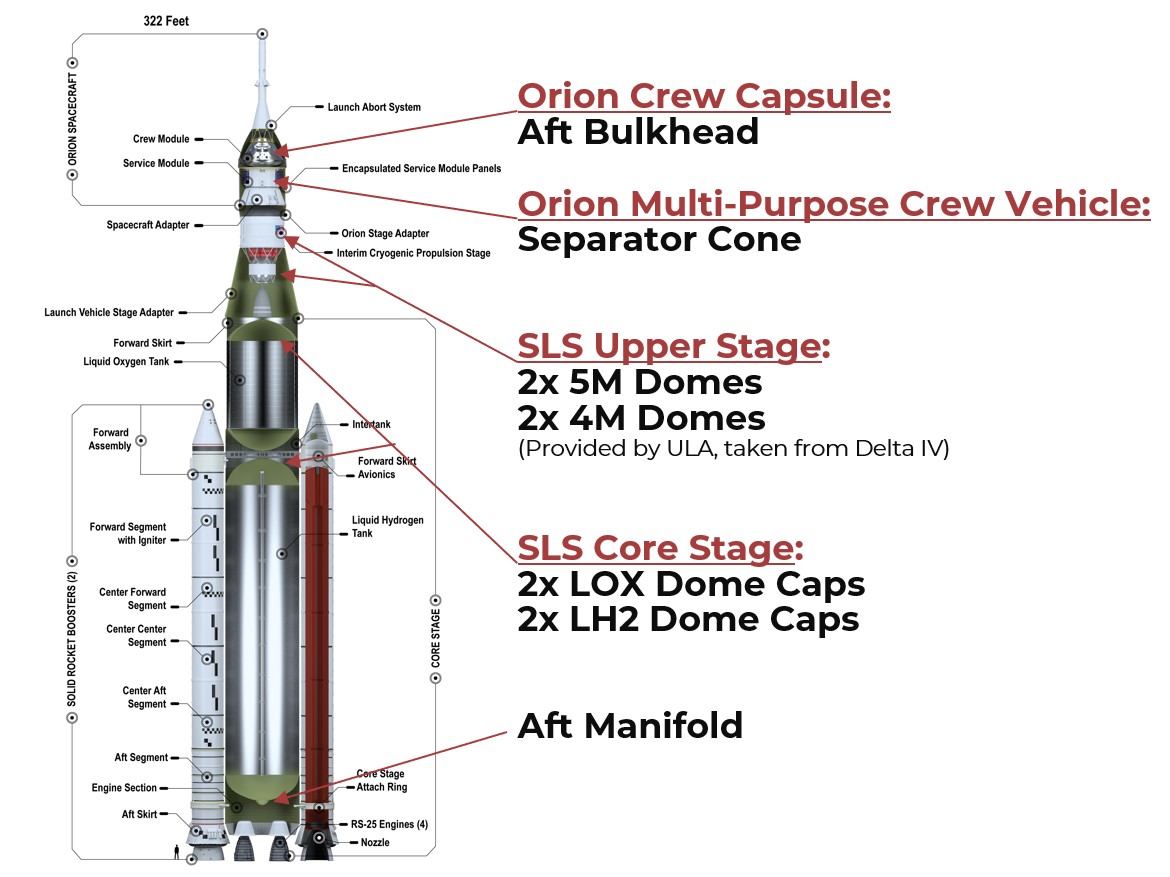

Some examples of Spincraft’s aerospace hardware credentials include:

- Precision attachment locations for flow direction vanes

- Propellent management devices (PMD) such as anti-vortex baffles and drain ports

- Airlocks & Docking Adaptors

- Crew habitation module components

Spincraft is a trusted partner in support of next-generation launch and space flight vehicle development with over a quarter-century of experience as one of the most critical solutions suppliers to the space sector. With leading-edge forming processes, Spincraft stands poised to facilitate and shape the next decade of space exploration and commercialization via our close collaborations with current and new partners. We invite you to connect and discuss how Spincraft can collaborate with you to solve your critical metal forming challenges with cost-effective solutions that will eliminate welds and reduce input weight.